Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

+44 (0)1302 831555

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LTD

Specialist Fasteners

for Sheet Metal

+44 (0) 1302 836010

+44 (0) 1302 831555

Tel:

Fax:

sales@npfasteners.com

Quality

Service

Reliability

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

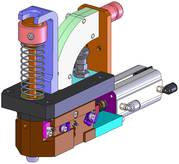

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Pias Nuts Type KP

Pias Nuts Type HN

Pias Nuts Type PNC

Rivtex Nuts Type RXM

Rivtex Studs Type RXS

Strux Studs Type SX

Installation Method & Performance

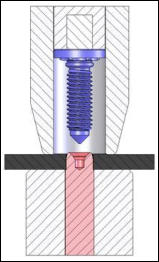

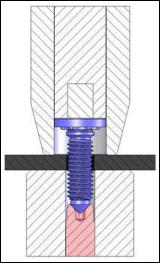

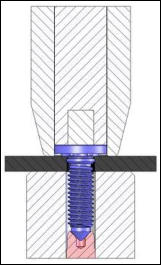

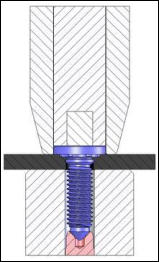

1. Starting Point

2. Press Stroke

3. Punching Process

4. Clinching Process

5. Finished sectional view

Punch Head

Die Block

Material & Finish

Steel - Stength Class 8.8 (8.8)

Steel - Stength Class 10.9 (10.9)

Unplated Steel (X)

Electro Zinc/Clear Plated Steel (ZI)

Electro Zinc/Nickel Plated Steel (ZN)

Electro Zinc/Heavy Plated Steel (ZI96)

Part Number Examples

Part number is made up as follows:

(Part code)-(Strength Class)-(Thread/Lead Style)-(Length)-

(Material/Finish code)

For example:

SX-8.8-M6-20-ZI (SX Stud-Class 8.8-M6 (flat thread lead)-20mm

long-electro zinc/clear plated steel)

SX-10.9-M8/2-25-ZI (SX Stud-Class 10.9-M8 (dog point thread

lead)-25mm long-electro zinc/clear heavy plated steel)

Downloadable Data Sheet

Back

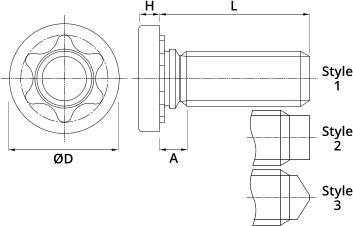

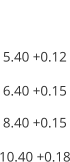

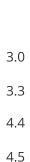

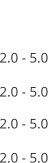

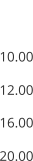

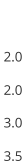

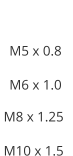

Dimensional

Standard Lengths

L ±0.25

Info

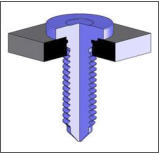

STRUX®-SX studs are available in thread sizes M5 to M10 for sheet thicknesses ranging from 2.0mm to 5.0mm, in

strength class 8.8 and 10.9. They are suitable for high load applications in thicker panels and due to their patented

under head geometry exhibit excellent performance. Strux® studs require a pre-pierced pilot hole which allows

accurate thread centring during installation and the Strux® installation tooling system.

Available in metric thread sizes in strength class 8.8 and 10.9 steel, they can be supplied as unplated or with a range

of electro plated zinc finishes including zinc/clear, zinc/nickel and zinc/thick film passivated.

Option of several thread lead styles: Style 1 (Standard): Flat point per EN ISO 4753-CH, Style 2: Dog point per EN ISO

4753-LD, Style 3: Coned half dog per WN-23-7 (similar to EN ISO 4753-PC)

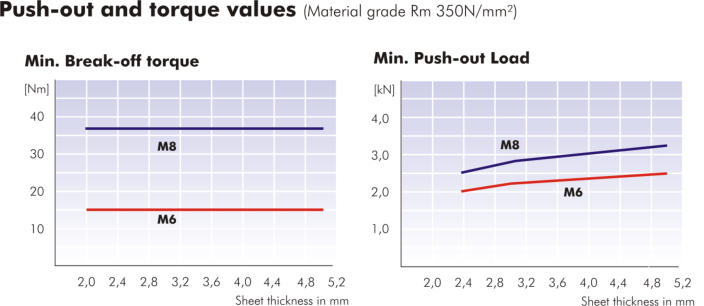

Benefits of Strux® SX studs include:

•

Reliable, flexible installation process

•

Designed for thicker panels from 2.0 to 5.0mm

•

Excellent torque-out and push-out performance

•

Suitable for steel and aluminium panels

•

Feeding options available to allow for multiple studs to be installation in one operation

Strux® is a trademark of Acument Intellectual Properties, LLC. USA.

STRUX®

SX STUDS