Magnesium

Magnesium Alloys

Zinc

Beryllium

Aluminium 1100, 3003, 3004, 5052, 6053

Cadmium

Aluminium 2017, 2024, 2117

Mild Steel 1018, Wrought Iron

HSLA Steel, Cast Iron

Chrome Iron (active)

430 Stainless (active)

302, 303, 321, 347, 410, 416 Stainless Steel (active)

Ni-Resist

316, 317 Stainless (active)

Carpenter 20Cb-3 Stainless (active)

Aluminium Bronze (CA687)

Hastelloy C (active) Inconel 625 (active) Titanium (active)

Lead/Tin Solder

Lead

Tin

Inconel 600 (active)

Nickel (active)

60% Ni 15% Cr (active)

80% Ni 20% Cr (active)

Hastelloy B (active)

Naval Brass (CA464), Yellow Brass (CA268)

Red Brass (CA230), Admiralty Brass (CA443)

Copper (CA102)

Manganese Bronze (CA675), Tin Bronze (CA903, 905)

410, 416 Stainless (passive) Phosphor Bronze (CA521, 524)

Silicon Bronze (CA651, 655)

Nickel Silver (CA 732, 735, 745, 752, 754, 757, 765, 770, 794

Cupro Nickel 90-10

Cupro Nickel 80-20

430 Stainless (passive)

Cupro Nickel 70-30

Nickel Aluminium Bronze (CA630, 632)

Monel 400, K500

Silver Solder

Nickel (passive)

60% Ni 15% Cr (passive)

Inconel 600 (passive)

80% Ni 20% Cr (passive)

Chrome Iron (passive)

302, 303, 304, 321, 347 Stainless (passive)

316, 317 Stainless (passive)

Carpenter 20Cb-3 Stainless (passive), Incoloy 825 (passive)

Silver

Titanium (passive), Hastelloy C & C276 (passive)

Graphite

Zirconium

Gold

Platinum

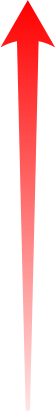

LEAST NOBEL - ANODIC / ACTIVE

(MOST LIKELY TO CORRODE)

MOST NOBEL - CATHODIC / PASSIVE

(LEAST LIKELY TO CORRODE)

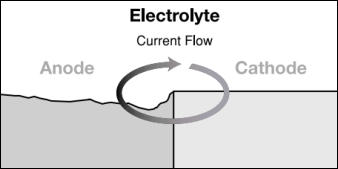

Galvanic Corrosion is an electrochemical process in which one metal corrodes preferentially to another when

both metals are in electrical contact, in the presence of an electrolyte.

Metals close to one another on the chart generally do not have a strong effect on one another, but the

farther apart any two metals are separated, the stronger the corroding effect on the one higher in the list.

This list represents the potential available to promote a corrosive reaction, however the actual corrosion in

each application is difficult to predict. Typically, the presence of an electrolyte (water for example) is

necessary to promote galvanic corrosion (order may change depending on the actual environment).

Self Clinching Fasteners

Broaching Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict Minerals Policy

Environmental Policy

SERVICES & SUPPORT

Material Thickness Chart

Material Hardness Chart

Galvanic Corrosion Info

Plating Specifications

Max. Recommended

Tightening Torques for

metric threads

Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and approved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict Minerals Policy

Environmental Policy

Opening Hours

Mon - Thu

08:00 - 17:00

Fridays

08:00 - 16:30

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LIMITED

Specialist Fasteners

+44 (0) 1302 836010

sales@npfasteners.com

GALVANIC CORROSION INFORMATION