Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Clinch Nuts

Flush Nuts

Blind Nuts

Miniature Nuts

Nyloc Nuts

Locking Nuts

Floating Nuts

Flush Head Studs

Flush Head Studs for

Stainless Steel

Reduced Flush Head Studs

Thin Panel Non-Flush Studs

High Strength Studs

Thin Panel High Strength

Studs

Flush Head Pins

Flush Head Tapered Pins

Concealed Head Studs

Through & Blind Standoffs

Grounding Standoffs

Thin Panel Standoffs

Quick Release Standoffs

Keylock Standoffs

Concealed Head Standoffs

Flush Panel Screw Assembly

Panel Fasteners

Phillips Head Panel Fasteners

Low-Profile Panel Fasteners

Plunger Assembly

Self-Clinching fastener

Do’s and Don’ts

Self-Clinching fastener

problem solving guides

Self-Clinch in harder panels

NORTHERN PRECISION LIMITED

Specialist Fasteners

+44 (0) 1302 836010

sales@npfasteners.com

Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and approved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict Minerals Policy

Environmental Policy

Opening Hours

Mon - Thu

08:00 - 17:00

Fridays

08:00 - 16:30

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

Type NS

Steel and 300 Stainless Steel Clinch Nuts Performance

Thread code

M2|M2.5|M3

Material

code

Test sheet

material

Installation

force (kN)

0

1

Aluminium

6 - 9

2

0

1

Steel

11 - 16

2

Push-out

(N)

Torque-out

(Nm)

285

410

770

485

570

1035

0.9

1.2

1.5

1.5

1.8

2.0

ALTM3|M3.5

0

1

Aluminium

11 - 14

2

0

1

Steel

13 - 27

2

290

415

850

490

580

1230

1.8

2.0

2.5

1.8

2.3

2.3

M4

0

1

Aluminium

11 - 14

2

0

1

Steel

17 - 28

2

310

490

980

495

655

1250

2.4

2.6

4.0

3.0

4.1

5.0

M5

0

1

Aluminium

11 - 16

2

0

1

Steel

18 - 40

2

320

510

990

535

815

1285

3.0

3.6

5.8

3.6

4.5

6.8

M6

0

1

Aluminium

17 - 32

2

0

1

Steel

26 - 38

2

990

1590

1600

1395

1760

1775

7.9

10.1

14.3

13.0

17.1

17.1

M8

1

2

Aluminium

18 - 33

1

2

1580

1600

1875

1890

13.5

18.2

18.9

20.1

Steel

26 - 38

2

M10

1

2

Aluminium

21 - 37

1

2

1690

1780

1965

2050

31.5

33.0

35.9

36.5

Steel

32 - 50

ALTM10

1

2

Aluminium

20 - 35

1

2

-

-

1910

-

-

30.0

32.5

33.0

Steel

29 - 45

1620

1695

2020

28.5

M12

1

1

Aluminium

30 - 42

2125

4700

39.0

84.0

Steel

44 - 70

400 Stainless Steel Clinch Nuts Performance

Thread code

M3

Material

code

Test sheet

material

Installation

force (kN)

1

2

304 Stainless

Steel

40

1

2

1

46

2

Push-out

(N)

Torque-out

(Nm)

720

1300

820

1630

1300

1780

1.9

2.1

4.2

5.1

5.1

7.0

44

304 Stainless

Steel

M4

M5

304 Stainless

Steel

44

50

51

1

60

2

M6

304 Stainless

Steel

65

2050

2610

17.2

19.5

1

66

2

M8

304 Stainless

Steel

80

2250

4620

19.8

23.5

1

80

M10

304 Stainless

Steel

2500

38.7

Aluminium Clinch Nuts Performance

Thread code

M3

Material

code

Test sheet

material

Installation

force (kN)

1

2

Aluminium

3.5 - 6.5

1

2

Push-out

(N)

Torque-out

(Nm)

440

540

530

760

0.7

1.0

3.1

3.2

4.0 - 6.8

Aluminium

M4

4.4 - 6.9

5.7 - 8.0

All performance figures are averages obtained over a range of installations and should

be used as an indicator only. Panel material, hole preparation, installation tooling and

method can affect part performance. We always recommend that you carry out your

own tests in the actual application. Please call our sales team and we will be happy to

provide you with samples as well as offering technical assistance.

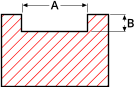

Testing Method

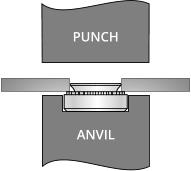

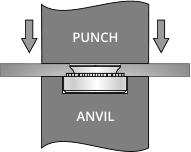

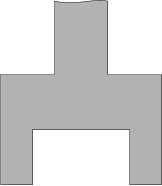

First punch or drill the correct size hole. Do not deburr or chamfer the hole prior to installation as this will

remove material required during the clinching process. It is preferable to install the fastener from the punch

side of the panel.

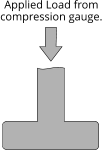

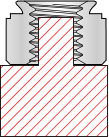

Place the fastener in the anvil with the shank facing up like in the diagram above. Locate the panel mounting

hole over the shank ensuring the panel is held level.

Apply a parallel squeezing force until the head is seated against the panel with no serrations visible. Do not

over squeeze the fastener into the panel as this will result in panel and possibly thread deformation.

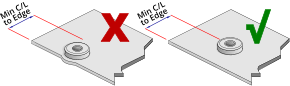

When installing Self-Clinching fasteners, please pay attention to the minimum hole centreline to edge and

parent material hardness limitations.

Bolt (Grade 5 min.) Ensure

full thread engagement

before applying load.

Hardened bushing with

sufficient wall thickness

to withstand applied

compression load.

Body Dia.

+ 1.6mm

Test panel.

Compression rig base.

Bolt (Grade 5 min.) A minimum

of 2 threads should extend past

the end of the fastener.

Test panel held

firmly in vice.

Applied torque

from dial measuring

torque wrench.

Flat washer

2 pitch min.

Push-out testing of Self-Clinching Nuts should be performed by the

gradual application of a load as shown.

Bushing height should be sufficient to allow free downward

movement of the nut during testing. The bushing bore must be

centred on the head of the nut.

Torque-out testing of Self-Clinching Nuts should be performed

by the gradual application of torque as shown, while the test

panel is securely held in a vice. The bolt must be of a sufficient

grade to resist thread stripping.

Torque must be gradually applied until failure is observed and

a maximum applied torque reading is recorded. Failure mode

is the nut turning in the panel or cam-out.

√

X

Do not remove any extra material or

chamfer the hole as this could result in

improper installation or reduced

performance.

HRB (ROCKWELL HARDNESS B SCALE)

Ensure that you are installing into a

panel that is ductile and at or below the

published maximum recommended

hardness for the fastener.

Ensure that attention is paid to the

minimum hole centreline to edge

dimension for each fastener. Installing

too close to an edge or bend could result

in improper installation or reduced

performance. Minimum centreline to

edge dimensions shown for each

fastener apply to one edge only. If this

distance is applied on multiple sides

there will be significant panel distortion

unless the panel edges are supported

during installation.

Material & Finish

Electro Zinc Plated Carbon Steel (ZI) parts are suitable for installation in ductile panels

with a maximum recommended hardness of 80 HRB.

300 Series Stainless Steel (A2) part are suitable for installation in ductile panels with a

maximum recommended hardness of 70 HRB.

400 Series Stainless Steel (400) parts are suitable for installation in ductile panels with a

maximum recommended hardness of 90 HRB.

Aluminium (AL) parts are suitable for installation in ductile panels with a maximum

recommended hardness of 50 HRB.

Part Number Examples

Part number is made up as follows:

(Type)-(Thread code)-(Material code)-(Material/Finish code)

For example:

NS-M3-0-ZI (Clinch Nut-M3-0.8mm min. sheet thickness-electro zinc plated carbon steel)

NS-M4-2-A2 (Clinch Nut-M4-1.4mm min. sheet thickness-stainless steel)

NS-M5-1-AL (Clinch Nut-M5-1.0mm min. sheet thickness-aluminium)

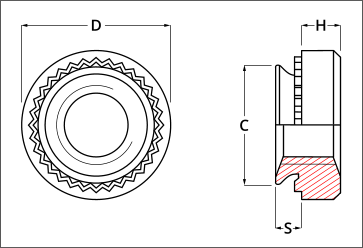

Dimensional Data

Installing 400 series parts

into hard stainless steel

panels

Self-Clinching fastener

Do’s & Don’ts

Self-Clinching fastener

problem solving guides

Downloadable

Data Sheet

Back

Installation

Info

Self-Clinching Nuts provide strong reusable female threads in panels that are too thin to be conventionally tapped.

Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst

providing a flush finish on the underside of the panel.

Like all self clinching fasteners they are installed using a parallel squeezing force so require access to both sides of

the panel.

Clinch Nuts are available in various thread sizes, manufactured from electro zinc plated steel, 300 and 400 series

stainless steel, and aluminium and are suitable for installation in ductile steel and aluminium panels with a

recommended maximum hardness of 80 HRB for steel parts, 70 HRB for 300 series stainless steel parts, 90 HRB for

400 series stainless steel parts and 50 HRB for aluminium parts.

B

-0.03

1.35

1.15

1.75

1.15

3.80

1.75

6.35

5.00

8.75

5.75

A

±0.05

7.57

6.78

8.38

7.57

11.53

9.17

7.62

13.13

9.53

7.62

Thread

codes

ALTM3

M2|M2.5|M3

M4

M3.5

M6

M5

M10

M8

M12

ALTM10

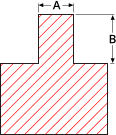

Anvil

type

Anvil Dimensions

Steel & Stainless Steel Clinch Nuts

Dimensions are in mm.

B

-0.03

1.15

1.15

3.55

1.75

3.80

A

±0.05

7.57

6.78

9.96

8.38

11.53

Thread

codes

M3.5

M2|M2.5|M3

M5

M4

M6

Anvil

type

Anvil Dimensions

Aluminium Clinch Nuts

Performance

SELF-CLINCHING

NUTS

Pocket Anvil

Protrusion Anvil