Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

+44 (0)1302 831555

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LTD

Specialist Fasteners

for Sheet Metal

+44 (0) 1302 836010

+44 (0) 1302 831555

Tel:

Fax:

sales@npfasteners.com

Quality

Service

Reliability

Installation Method

Using your prefered type of

installation tool. KJ60 air tool

and N200 hand tool shown for

reference only.

Ensuring that you are using the

correct grip size rivet nut for the

panel you will be installing into,

screw the rivet nut fully on to

the tools threaded mandrel.

Follow the instructions specific

to your tool to set the correct

stroke length for proper rivet

nut placement. Fully insert the

rivet nut into the hole in the

work piece.

Ensuring that you are holding

the tool perpendicular to the

work piece, operate the tool to

set the rivet nut in place.

Unscrew the threaded mandrel

from the rivet nut.

That’s it. Your rivet nut is now

installed.

To ensure that the rivet nut

performs as intended it is

important that an optimum

bulge is formed.

Material & Finish

Heavy Duty Electro Zinc Plated Steel (ZI96)

Heavy Duty Electro Zinc Plated Steel for up to

12.9 bolts (HTZI96)

Stainless Steel (A2)

Stainless Steel for up to 12.9 bolts (HTS)

Aluminium (AL)

Aluminium (AL) for up to 8.8 bolts (HTA)

Brass (BR)

Part Number Examples

Part number is made up as follows:

(Type) (Thread code) (Grip Code) (Material/Finish code)

For example:

OPTI-BCLF M6 0525 ZI96 (BCT Large Flange Bulge Controlled-

M6-suitable for 0.5-2.5mm panel thickness-heavy duty

electro zinc plated steel)

OPTI-BCLF M8 3050 HTS (BCT Large Flange Bulge Controlled-

M8-suitable for 3.0-5.0mm panel thickness-high strength

stainless steel for use with up to 12.9 bolts)

M4 x 0.7

7.0

10.00

14.5

1525

1.5 - 2.5

0.80

6.90

15.5

2535

2.5 - 3.5

8.0

16.5

3545

3.5 - 4.5

17.5

4555

4.5 - 5.5

1.5

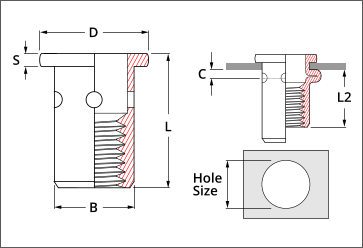

Dimensional

Thread

Size

Hole Size

+0.1 -0.0

D

L

Nom.

L2

Ref.

Grip

Code

To suit panel

thickness

(min - max)

S

B

±0.09

M8 x 1.25

11.0

16.00

20.5

1030

1.0 - 3.0

1.50

10.90

24.0

3050

3.0 - 5.0

12.5

26.0

4565

4.5 - 6.5

28.0

6080

6.0 - 8.0

M10 x 1.5

13.0

19.00

26.0

1035

1.0 - 3.5

2.00

12.90

29.0

3560

3.5 - 6.0

16.0

34.0

6085

6.0 - 8.5

C

Min.

2.3

2.7

M6 x 1.0

9.0

13.00

19.5

0525

0.5 - 2.5

1.50

8.90

20.0

2540

2.5 - 4.0

10.5

21.5

4055

4.0 - 5.5

23.0

5570

5.5 - 7.0

2.0

M5 x 0.8

8.0

11.00

17.0

0520

0.5 - 2.0

1.00

7.90

18.0

2030

2.0 - 3.0

10.0

19.0

3040

3.0 - 4.0

20.0

4050

4.0 - 5.0

1.8

0515

0.5 - 1.5

14.0

Info

BCT Large Flange Bulge Controlled is a new type of high performance rivet nut designed to provide much improved

performance over conventional rivet nuts.

BCT provides a strong captivated thread in panels and is ideally suited to applications where only one side of the

panel is accessible such as box or tube section.

Unlike conventional rivet nuts, BCT Bulge Controlled features a controlled upset point and larger bulge formation

which allows for perfect installation even in oversize or irregular holes. The bulge is formed without placing load on

the panel or hole wall, so they are especially suitable for use in softer or brittle materials such as composites or

sandwich sections for example.

Available in thread sizes M4 to M10, in RoHS compliant heavy duty electro zinc plated steel (giving 96 hour salt spray

protection), heavy duty electro zinc plated high strength steel suitable for use with up to 12.9 bolts, 304 stainless

steel, high strength stainless steel suitable for use with up to 12.9 bolts, aluminium, high strength aluminium

suitable for use with up to 8.8 bolts and brass. They can be installed into panels as thin as 0.5mm and as thick as

8.5mm. In addition to standard grips they can also be manufactured in grip ranges to suit your exact application

requirement.

Requiring the same installation tooling as conventional rivet nuts, tools range

from very low cost hand tools for low volume, to air powered automatic

installation guns for high volume applications.

BCT has an advantage over other captivated fasteners because they can be

installed on site or used for repair work to replace a previously installed

fastener that has failed. The advantage of installation from one side of the

application means that access to the back of the panel is never required.

BCT is a registered trademark of BBA srl.

BCT

®

LARGE FLANGE

BULGE CONTROLLED

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Reduced Head Imperial Hole

Size (TS)

Reduced Head Splined Body

Imperial Hole Size (TSK)

Reduced Head (TSE)

Reduced Head Splined Body

(TSEK)

Reduced Head Closed End

(TSB)

Reduced Head Closed End

Splined Body (TSBK)

Flat Head (FRS)

Flat Head Splined (FRSK)

Flat Head Closed End (FRSB)

Flat Head Closed End Splined

Body (FRSBK)

Countersunk Head (CRS)

Countersunk Head Splined

Body (CRSK)

Countersunk Head Closed

End (CRSB)

Countersunk Head Closed

End Splined Body (CRSBK)

Reduced Head Half Hexagon

Imperial Hole Size (HRS)

Reduced Head Half Hexagon

(HRSE)

Reduced Head Half Hexagon

Closed End (HRSB)

Reduced Head Full Hexagon

(HRSE/F)

Reduced Head Full Hexagon

Closed End (HRSB/F)

Flat Head Full Hexagon

(FHRS/F)

Flat Head Full Hexagon

Closed End (FHRSB/F)

BCT Reduced Head Multigrip

(OPTI-TS)

BCT Reduced Head Multigrip

Splined Body (OPTI-TSKN)

BCT Large Flange Multigrip

(OPTI-LF)

BCT Large Flange Multigrip

Splined Body

(OPTI-LFKN)

BCT Reduced Head Bulge

Controlled (OPTI-BCTS)

BCT Reduced Head Bulge

Controlled Splined Body

(OPTI-BCTSKN)

BCT Large Flange Bulge

Controlled (OPTI-BCLF)

BCT Large Flange Bulge

Controlled Splined Body

(OPTI-BCLFKN)

Installation Tools, Spares and

Servicing