Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

+44 (0)1302 831555

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LTD

Specialist Fasteners

for Sheet Metal

+44 (0) 1302 836010

+44 (0) 1302 831555

Tel:

Fax:

sales@npfasteners.com

Quality

Service

Reliability

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Crown-nuts

Crown-nut Round

Crown-nut Round Headed

Crown-nut Round Headed -

for Push Fit Castors

Crown-nut Square

Crown-nut Square Headed

Crown-nut Square Headed -

for Push Fit Castors

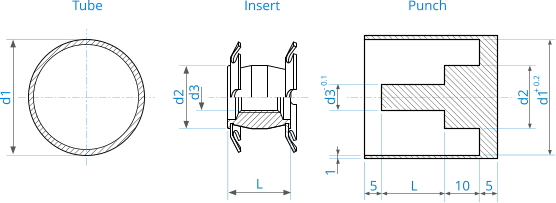

Sleeved Anvil

Un-Headed Crown-Nut Installation

1) Fabricate a punch appropriate for the type of Crown-Nut and the depth of installation required.

2) Ensure that the receiving tube is firmly secured.

3)

Place

the

Crown-Nut

inside

the

punch,

making

sure

that

the

crowns

are

orientated

correctly,

(bent towards the punch, as shown).

4)

Place

the

Crown-Nut

and

punch

assembly

on

the

head

of

the

tube.

It

is

important

that

the

end

of

the

tube

is

a

uniform

shape

and

cut

perpendicular

to

the

side

of

the

tube,

as

any

cutting

errors

will

be detrimental to the fit and function of the

Crown-Nut

.

5) Gradually apply pressure until the end of the run and the punch bottoms out.

6) Remove the punch.

Material & Finish

Electro Zinc Plated Steel

Part Number Examples

ITT2S M6 19.5

2 crowns round type CROWN-NUT with an M6 thread,

suitable for round tube section with an internal dimension

ranging from 19.5mm to 20.9mm

ITT2S M10 26.0

2 crowns round type CROWN-NUT with an M10 thread,

suitable for round tube section with an internal dimension

ranging from 26.0mm to 28.0mm

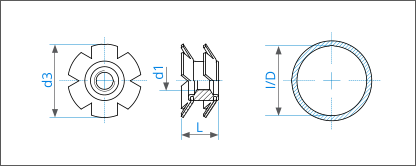

Dimensional

Part Number

d3

(Crown Diameter)

I/D

(Tube Internal Size)

L

(Total Length)

Non-binding dimensions in mm.

It is advisable to carry out preliminary assembly tests to determine the size that gives optimal performance in your application.

Application & Installation

Ideal for applications subject to pull forces. Not

suitable for push loads. Not having a head allows

fitting of the Crown-nut insert inside the tube

section at your own defined depth.

Press fit: gradually increase pressure on the insert

until the required depth is reached. It is highly

recommended that a sleeved punch is used to

ensure the insert is installed squarely and at the

correct depth (see below).

d1

(Thread)

M6

M8

M10

12.8

13.6

14.7

14.7

17.0

18.1

18.7

19.7

21.0

21.7

11.8 - 12.2

12.6 - 13.2

13.2 - 13.8

13.8 - 14.2

15.2 - 16.1

15.7 - 17.1

16.4 - 17.7

17.9 - 19.3

18.9 - 20.2

19.5 - 20.9

12.5

10

12.5

12.5

10

9.4

9.5

9.5

9.5

11

23.2

24.6

25.4

26.6

27.6

28.4

30.6

31.8

33.8

17.0

21.4 - 22.4

22.1 - 23.4

22.7 - 24.0

24.6 - 25.6

25.3 - 26.6

26.0 - 28.0

28.4 - 29.8

29.8 - 30.8

31.7 - 32.9

15.2 - 16.1

10

10

10.5

9.5

10

10

11.5

10

13

12.5

18.1

18.7

20.0

21.5

23.4

25.4

26.5

27.6

28.4

30.6

15.7 - 17.1

16.4 - 17.7

17.9 - 19.3

19.5 - 20.9

21.4 - 22.4

22.7 - 24.0

24.6 - 25.6

25.3 - 26.6

26.0 - 28.0

28.4 - 29.8

12.5

12.4

13

14.5

13

14

13.3

13.5

13

15

31.8

33.6

37.0

39.0

41.3

43.5

20.3

21.0

21.7

23.2

29.8 - 30.8

31.7 - 32.9

34.8 - 36.1

36.0 - 38.0

38.4 - 40.4

41.4 - 42.4

17.9 - 19.3

18.9 - 20.2

19.5 - 20.9

21.4 - 22.4

14

15

16

15.3

15.5

16.4

13

12.5

12.5

13.5

25.0

26.2

28.9

30.7

33.8

37.3

39.0

41.6

50.0

60.0

22.1 - 23.4

24.6 - 25.6

26.0 - 28.0

28.4 - 29.8

31.7 - 32.9

34.8 - 36.1

36.0 - 38.0

38.4 - 40.4

47.5 - 48.8

56.0 - 58.0

14

13.8

15

13.5

14.3

16.5

15.2

16

17

16.8

ITT2S M6 11.8

ITT2S M6 12.6

ITT2S M6 13.2

ITT2S M6 13.8

ITT2S M6 15.2

ITT2S M6 15.7

ITT2S M6 16.4

ITT2S M6 17.9

ITT2S M6 18.9

ITT2S M6 19.5

ITT2S M6 21.4

ITT2S M6 22.1

ITT2S M6 22.7

ITT2S M6 24.6

ITT2S M6 25.3

ITT2S M6 26.0

ITT2S M6 28.4

ITT2S M6 29.8

ITT2S M6 31.7

ITT2S M8 15.2

ITT2S M8 15.7

ITT2S M8 16.4

ITT2S M8 17.9

ITT2S M8 19.5

ITT2S M8 21.4

ITT2S M8 22.7

ITT2S M8 24.6

ITT2S M8 25.3

ITT2S M8 26.0

ITT2S M8 28.4

ITT2S M8 29.8

ITT2S M8 31.7

ITT2S M8 34.8

ITT2S M8 36.0

ITT2S M8 38.4

ITT2S M8 41.4

ITT2S M10 17.9

ITT2S M10 18.9

ITT2S M10 19.5

ITT2S M10 21.4

ITT2S M10 22.1

ITT2S M10 24.6

ITT2S M10 26.0

ITT2S M10 28.4

ITT2S M10 31.7

ITT2S M10 34.8

ITT2S M10 36.0

ITT2S M10 38.4

ITT2S M10 47.5

ITT2S M10 56.0

Info

An Insert for use inside the end of round tube section

The Crown-nut is a revolutionary solution for the creation of a strong reusable female thread at the end of round or

square section tubes. Crown-nut solves the issue of how to securely fix to the end of tube section, guaranteeing

superior torque-out and pull-out performance. The product range offers solutions for round tube and square

section and is available in a wide range of sizes. A version is also available that is designed to accept push-fit castors.

Advantages of the Crown-nut

•

Can be installed into round tube section with a wide internal diameter tolerance range. Thanks to the

flexibility of the crown design, the same item code can be used for a range internal diameters.

•

The crown is designed so that the shape of the tube section is not altered during installation, guaranteeing

the aesthetics of the external surface.

•

Crown-nuts are easy to install and are cost effective. The press-in fit is fast and easy, enabling the elimination

of traditional and costly assembly processes such as welding and staking.

Note

After the insertion of the Crown Nut avoid heat treatments, galvanization and other heating operations that could

compromise the characteristics of the product.

Type ITT2S

CROWN-NUT

ROUND