Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Spring Steel Fasteners

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

Keep-Nut Guide

Keep-Nut Flush

Keep-Nut Flanged

Keep-Nut Stud

Master-Plate Guide

Master-Plate Stud

Master-Plate Blind Standoff

Master-Plate Through

Standoff

Master-Plate Through Nut

Deform-Nut Guide

Deform-Nut Type TC

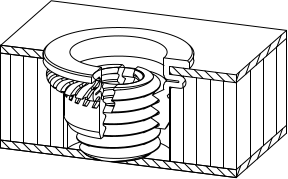

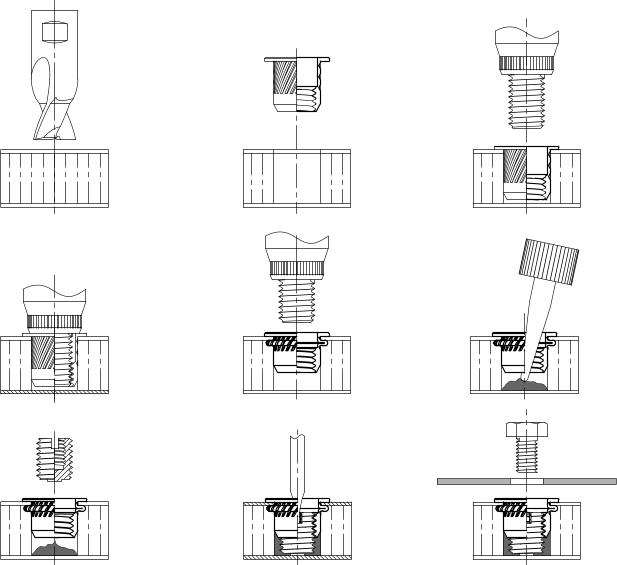

DEFORM-NUT® SYSTEM

FOR SANDWICH PANELS

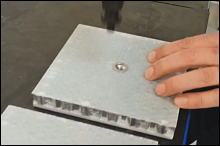

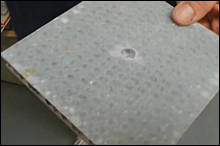

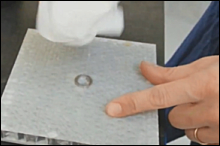

1. Drill the correct hole from one side of the panel (blind hole)

2. Insert the rivet nut in the hole

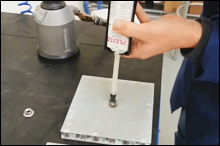

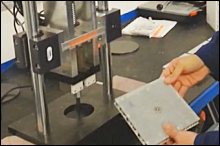

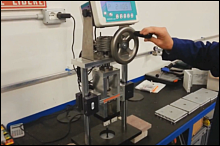

3. Using rivet nut setting tool, pull up the rivet nut to to attach it to the top skin of the sandwich panel

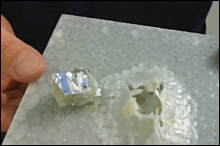

4. Inject structural adhesive

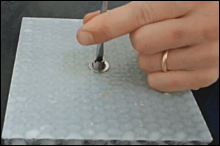

5. Insert and screw down the threaded adjusting insert until it reaches the bottom skin of the sandwich panel

6. Fastener is ready for use (time to full strength is dependant on structural adhesive properties)

Deform-Nut® is a patented threaded insert system that combines mechanical anchoring and structural

adhesive to provide strong load-bearing threads in sandwich panel materials (with a honeycomb or

composite internal structure).

Expensive or complex solutions such as resin potting or bonding of bushes and tie rods can be avoided.

Furthermore, Deform-Nut allows you to use the same type of product in a wide range of sandwich panel

materials and thicknesses, is easy and quick to install and doesn't require any further processes or finishing

after installation.

Deform-Nut can be used in any composite material panel, resins, carbon fibre, light alloy, and more.

The 3 stage system comprises:

•

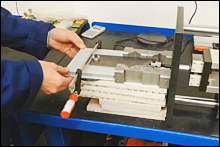

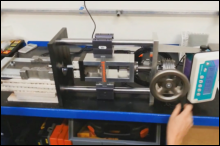

A special rivet nut style fastener which is riveted in to the top skin of the panel using conventional

rivet nut hand or air tooling

•

Structural adhesive is then injected into base of the rivet nut

•

A separate adjusting nut is then screwed into the rivet nut until it bottoms out on the bottom skin,

displacing the adhesive into the surrounding structure to increase load strength